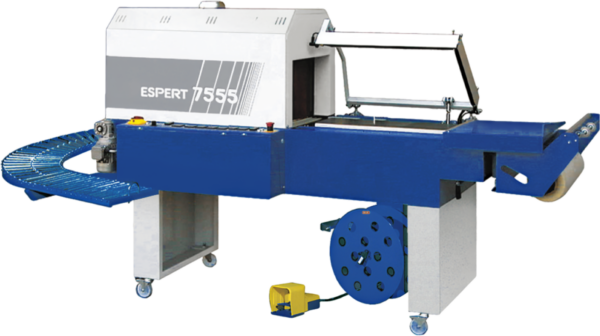

ESPERT 7555 EV

semi-automatic heat-shrinking l-sealerSEMIAUTOMATIC SHRINK-WRAPPER: PERFECT FOR LARGE SIZE PRODUCTS

These models have been conceived to be used when more automation is required, in fact the only thing the operator has just to do is to insert the product into the film and to move it onto the sealing area, as the rest of the working cycle ( sealing, product removal and transfer inside the shrink tunnel) happens automatically. Ideal for medium-high output productions that need to wrap single and multiple products. Easy changement of size according to product dimensions and shape.

TECHNICAL SPECIFICATIONS

MORE INFORMATION

An alternative choice to “one-step®” systems in order to increase production though beeing very easy to use..

- Innovative design

- High quality standards

- High productions outputs

- Fully automatic working cycle

- Pneumatical working: a pneumatic cylinder closes the sealing-bars, this way the conveyor belt starts operating and transfers the product into the shrink tunnel for being shrinked.

- Opening and closing of the sealing-bars (with a pedal or automatically), sealing-time and conveyor belt moving time controlled by a timer

- Two independent conveyor belts in the sealing area and in the shrinking

- The height of the sealing area is adjustable according to the product size

- An efficient safety system guarantees the operator’s hands security, according to the CE regulations

- The shrink tunnel, integrated in the machine structure, is equipped with a rolling-rods conveyor belt with adjustable speed by means of a direct current variator on the control panel. The tunnel itself has shutters for air regulation in order to obtain the best shrinking even in difficult conditions.

- Available options: Boomerang roller conveyor, scrap-rewinder

- The machine works with PVC (BLUE FILM), polyolefin hot thermo-sealing and also shrinkable films (GREEN FILM –GOLDEN FILM)

Machine made according to CE rules.

DATA SHEET

SPECIFICATIONS ESPERT 7555 EV

- Power supply: 240/400 V – 3 Ph + N

- Power required: 10 KW

- Overall machine dimensions: 2730 x 950 x 1500 mm

- Working table height: 930 mm

- Tunnel entrance dimensions: 570 x 240 mm

- Tunnel lenght: 900 mm

- Weight: 340 kg

- Max sealing area: 750 x 550 mm

- Max product height: 150 mm

- Impulse sealing system: Lama superiore

- Max film width: 700 mm

- Compressed air consuption: 3 Nl/cycle

- Compressed air pressure: 6 bar

- Output: 600 – 900 pz/h

notes: Technical data subject to variations without prior notice

Output depends on the operator and the type of the package

PHOTOS AND VIDEO

ESPERT 7555 EV PACKS YOUR PRODUCTS

CONTACTS and SUPPORT

For any technical assistance needs or information about our products, our customer support is at your disposal. We offer a qualified and prompt after-sales service to ensure continuous support. Contact us to find out how we can help you optimize your packaging and wrapping processes with customized solutions.

HEADQUARTER

ITALDIBIPACK S.p.A.

Via Europa, 35

20005 Pogliano Milanese (MI), Italia