We are proud to share ‘For a Better World’ – our action plan for a more sustainable world.

We are encouraging our staff, our Customers, our suppliers to make a greater impact together and achieve a better world.

For this reason, we have defined four global objectives to be achieved: to promote eco-sustainability, to support the training of qualified technical and commercial personnel in the realization and promotion of eco-friendly and innovative systems with the lowest possible environmental impact, to make our Customers responsible for purchasing materials with minimal impact or even ‘zero’ impact where possible, and to do business in a way that is conscious and respectful of people and the ecosystem in which we live.

Aware that sustainability is important to all of us, it is for this reason that we have been collaborating for several years with some of the realities and Companies most attentive to these issues. In fact, Italdibipack has been offering sustainable products, services and packaging solutions for many years now, looking for new ways to reduce the use of the most harmful plastics.

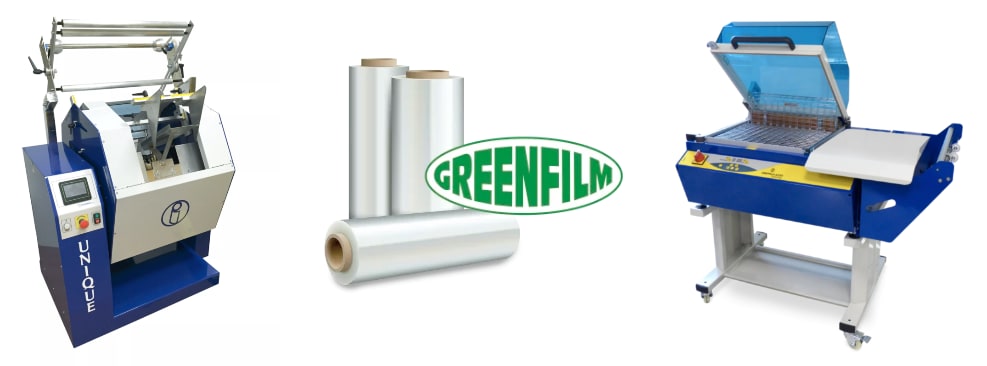

For this particular purpose, Italdibipack has designed a truly eco-friendly packaging machine capable of working without the use of plastics either during the packaging cycle or during product introduction: UNIQUE flowpack machine designed by Italdibipack R&D is able to wrap the product in a plastic material that complies with UNI EN 13432. This European standard stipulates that in the normal composting cycle, elements must decompose by 90% within 3 months and after 6 months they must be digested by microorganisms by 90%. UNIQUE flowpack machine, moreover, can make multipack without the use of trays, eliminating the use of plastics or any other material as containers for products such as fruit, vegetables, sweets and food in general.

With UNIQUE flowpack machine, all packaging cycle can be made, in addition to standard materials, also with ecofriendly materials, like for example : MATERB, PLA, BIOBASED BOPP FILM.

The main advantages of bio-based plastic products over conventional plastics is that no fossil resources are used in their production, but only renewable natural resources, contributing to the reduction of greenhouse gas emissions, both in the initial processing phase and in the eventual final phase in the incinerator.

Italdibipack has always collected needs and transformed them into winning solutions, guaranteeing the result, through new intelligent investments to give coherence to its history as a manufacturer of packaging machines and supplying the relevant consumables = packaging film, increasingly eco-sustainable in step with the changes of an ever greener and cleaner world. Making packaging (machines and materials) a virtuous and essential component in the life of man and product, thanks to indispensable peculiarities: preservation – protection – image – distribution…

The best hygienic protection for a product has always been a flexible plastic cover, which allows a total view of the product, preserving it from infected bacteria. Today, however, the aesthetic side, the performance at breakage, the degree of transparency, the tightness of the seals, is no longer sufficient to evaluate the packaging of a product. The life of the packaging, after the use for which it was produced, has become an increasingly important topic today. The focus is on the use of green plastic films. Since 2005, Italdibipack has created the GREEN FILM line, a polyolefin packaging material line recyclable, and has developed, in collaboration with its strategic partners, a new formulation to make the packaging of products, the least problematic for the environment. To this end, it has invested and collaborated with one of the most avant-garde material manufacturers, in the formulation of recyclable heat-shrinkable materials, producing co-extruded polyolefins with high physical and mechanical properties and high shrinking capacity at low temperatures, environmentally friendly materials that at the same time reduce energy consumption. It is with this aim in mind that Italdibipack has developed a shrink wrapping machine capable of reducing electricity consumption thanks to an electronic board designed for this purpose.

All the DIBIPACK EVX machines, Italdibipack’s most popular and well-known model, have been equipped with an electronic board made by Italdibipack R&D capable of reducing costs thanks to energy savings, allowing the:

Italdibipack in collaboration with the first producer of biodegradable and compostable shrink film, awarded as the best packaging innovator of 2021, contributes to the promotion and diffusion of packaging films, produced with biopolymers certified compostable according to SIST EN 13432:2001 and SIST EN 14995:2007. With innovative production plants to produce biodegradable and compostable films for the food and non-food industry, focused on reducing the rate of plastic pollution and CO2 emissions, our packaging films are produced from natural sources: during production they do not release harmful gases and are therefore non-polluting, with almost no environmental impact, and with an end-of-life and closure ring.

Companies that change normal plastics into compostable films will begin to realise a new era of environmentally sustainable packaging, combined with the main objective of the ongoing United Nations Climate Change Conference (COP26) to accelerate the transition from fossil fuel – based materials to bio-based materials for the packaging industry, this means replacing petrochemical plastics with a ‘Plastic Free’ bio-based material to reduce greenhouse gases (global warming) and drastically reduce post-consumer waste (pollution of the entire globe).

These films can be recycled, bio-composted or incinerated without harming the environment. With a safe end-of-life and closure cycle. The best solution for those who, like us, believe in a more sustainable and clean planet.

Our bio-films are used for food and non-food packaging, cover a wide range of packaging applications.

All these new films have been tested and are compatible with our packaging machines, offering high quality performance.

The demarcation line with the old industrial models seems then to be drawn. Being environmentally sustainable is therefore possible. Choosing an ecological film is therefore possible today… It is here that Italdibipack wants to make the difference a greater diffusion and promotion of these materials would admit a reduction in costs thanks to the increase in quantities.

Italdibipack would like to contribute more and more to promoting the use of these films to its Customers and potential ones, through collaboration with its strategic partners in the production of ecological films designed ad hoc for application segments of its customers, researching the best and most sustainable formulations that are eco-friendly but also economically sustainable.